Clothing made from recycled down and fabric made with polyester fibres from recycled plastic bottles. This is the idea launched by the Japanese chemical giant Toray. The company – that makes the carbon fiber for cars and planes, and has also contributed to the materials of the latest iPhone – has always been very attentive to sustainability and few day ago announced its partnership with the Japanese global apparel retailer Uniqlo for the creation of a new clothing line.

The first part of the project is the development of down clothing employing reclaimed down and DRY-EX apparel incorporating fabric from polyester fibres made with recycled PET bottles. This new initiative, part of a longstanding strategic partnership between the two companies, will contribute to sustainability by giving consumers access to merchandise that optimises the use of valuable resources.

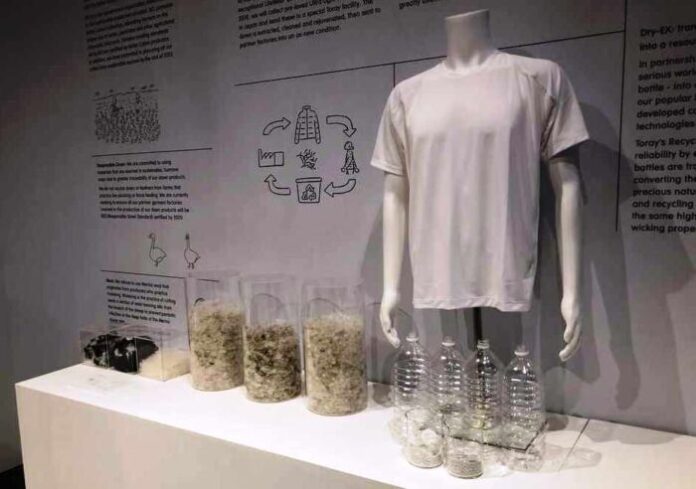

New DRY-EX pieces incorporating polyester from recycled PET bottles

DRY-EX is a revolutionary material that quickly wicks away sweat and moisture. From 2020 Spring/Summer UNIQLO will begin to introduce DRY-EX items of clothing that incorporate high-value-added polyester fibres derived from reclaimed PET bottles.

This is a milestone because, while fibres made from reclaimed plastic bottles have been commercially available for some time, it has been hard to produce fibres featuring special cross-sections and fine fibres, owing to contaminants in PET bottles. Another challenge to address has been that plastic bottles yellow as they age.

Toray’s contaminant filtering technology overcomes these issues, making it possible to manufacture fibres whose features are commensurate with those of fibres from plastic made directly from petrochemical feedstock, including those with special cross-sections. Another advance is Toray’s Recycling Identification System, which enhances reliability by ensuring that fibres derived from plastic bottles are traceable.

For the second part of the project, Uniqlo stores will collect used Ultra Light Down items from customers. A new Toray-developed system will extract material from Ultra Light Down pieces, to be cleansed for use in new down merchandise. Collections* will start later in September this year initially only in Japan, and some down products from the 2020 Fall/Winter season will employ this recycled material.

Conventionally, the stuffing in duvets and other objects incorporating down is manually removed. Such processes are arduous with Ultra Light Down items because of their thin shells and complex construction. By developing special extraction machinery, Toray has fully automated cutting, stirring and separating, and recovery, for 50-fold the process capacity of manual processes, thus greatly alleviating workloads.

Since Toray’s founding in 1926, the company has always believed that materials can change lives, true to our fundamental corporate principle of contributing to society. At the Toray Group, they make it their mission to deliver innovative technologies and advanced materials that provide real solutions to the challenges the world faces with balancing development and sustainability.